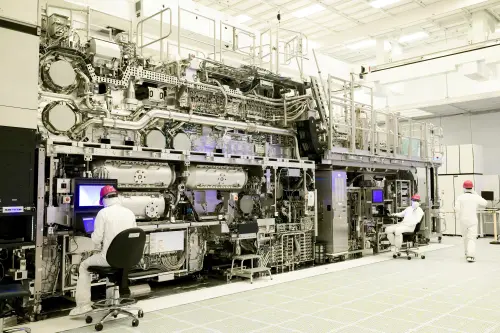

In San Jose, California, on Feb 24, Intel announced that the first two cutting-edge lithography machines from ASML Holding are now in production at their factories, showing early data indicating higher reliability compared to previous models.

During a conference, Intel senior principal engineer Steve Carson revealed that Intel has successfully produced 30,000 wafers in a single quarter with ASML's high numerical aperture (NA) lithography machines. Last year, Intel became the world's first chipmaker to obtain these machines, expected to manufacture smaller and faster computing chips than their predecessors. This marked a strategic shift for Intel, previously trailing in adopting the earlier generation of extreme ultraviolet (EUV) lithography machines.

Unlike the previous EUV models, which took Intel seven years to fully integrate into production due to reliability issues, Carson highlighted that ASML's new high NA machines are approximately twice as reliable in initial testing. Carson emphasized the benefits of the high NA machines, stating, "We're getting wafers out at a consistent rate, and that's a huge boon to the platform."

The new ASML machines, using light beams to print features onto chips, achieve the same results as earlier models with fewer exposures, thereby saving time and costs. Initial results at Intel's factories demonstrated that the high NA machines can accomplish tasks previously requiring three exposures and around 40 processing steps with just one exposure and a limited number of processing steps.

Intel plans to leverage the high NA machines to develop its 18A manufacturing technology, expected to enter mass production for a new generation of PC chips later this year. While Intel intends to fully transition to high NA machines with its upcoming 14A manufacturing technology, they have not provided a specific date for its mass production.